Continuously Variable Transmission : Components , Working , Types , Advantages and Disadvantages

What is a CVT and does it work? How CVTs (Continuously Variable Transmissions) work. An explanation of a pulley based CVT, and how this transmission does not. A continuously variable transmission (CVT) is a type of automatic car transmission system that uses a pulley and belt system to provide an unlimited range of gear ratios. In 1984, the Japanese automobile manufacturer, Subaru, introduced the electronic continuously variable transmission (ECVT) in a hatchback called Subaru Justy. A continuously variable transmission in a vehicle senses the accelerator input with engine load and get shifted to the desired speed or torque gear ratio automatically, in other words we can say that a cvt transmission is one of the simplest types of automatic transmission that provides continuous uninterrupted power within a specified range of speed and torque ratios. The CVT is the newest type of transmission. It is sometimes referred to as the shiftless transmission and is a type of automatic. What Does CVT Stand For? Autotrader explains the term CVT stands.

A CVT or Continuously Variable Transmission is an automatic, single speed, and gearless transmission that can shift through an infinite number of gear ratios.

A continuously variable transmission (CVT) is a transmission that operates on an ingenious pulley system that automatically varies the transmission ratio, allowing an infinite variability between highest and lowest gears with no discrete steps or shifts. CVTs provide more useable power, better fuel economy and a smoother driving experience than traditional transmissions that use gearboxes with fixed numbers of gear sets.

A continuously variable transmission system is a type of automatic transmission in which an arrangement of pulleys and belts made it possible for a drive to achieve n-number of continuous gear ratios within a range (depends on the design).

Read more : Why there is no clutch in gearless scooter – CVT Explained

A continuously variable transmission in a vehicle senses the accelerator input with engine load and get shifted to the desired speed or torque gear ratio automatically, in other words we can say that a cvt transmission is one of the simplest types of automatic transmission that provides continuous uninterrupted power within a specified range of speed and torque ratios.

COMPONENTS OF CVT:

1. Clutches

I. Primary clutch

The primary clutch is an advanced form of centrifugal clutch and is typically mounted to the output end of the engine crankshaft. The clutch has two sheave faces; one that is laterally fixed (stationary sheave), and one that can move in and out to engage the belt (moveable sheave). In most systems, at idle the sheave surfaces are spread at their widest spacing, the belt is riding on the post or shaft at the smallest diameter of the clutch, and the belt is not pinched by the sheave faces. This provides a 'neutral' position that allows the engine to idle without transmitting power to the wheels.

II. Secondary clutch

The secondary clutch is mounted to the input shaft of the transmission, transaxle, or the like. In modern CVT systems such as those used in recreational vehicles, the secondary clutch has two functions: as a 'slave' to the primary clutch and to provide a torque sensing element.

2. Pulleys

In Cvt pulleys play an important role as the conical shape pulleys integrated over input and output shafts are the reason for continuously variable transmission's continuous n-number of speed and gear ratios, due to the different cross section of these conical pulleys multiple torque and speed ratios are obtained.

Two pair of conical pulleys each for input and output shafts are used in a basic continuously variable transmission that are-

1. Fixed input pulley-

It is a conical pulley mounted over the input shaft (on the right-hand side), this pulley does not move (too and fro) over the shaft but rotates with the input shaft, usually fixed pulley is smaller in size.

2. Fixed output pulley

It same as fixed input pulley but unlike fixed input shaft this shaft is placed on the left-hand side over the output shaft.

3. Feeding input pulley or sheave-

It is the type of conical pulley which is mounted over the input shaft and have inner splines meshed with the shaft splines in such a fashion that it can move (too and fro) as well as rotates with the input shaft. the too and fro moment of this shaft over the input shaft make it possible to shift gear ratios.

4. Feeding output pulley or sheave

Same as moving input pulley but unlike moving input shaft, this shaft is placed on the right-hand side over the output shaft.

3. Shafts

Same as manual transmission type 2 shafts are needed by Cvt transmission to transfer power from engine to the final drive that are-

Argon and helium. 1. Input shaft-

Same as the manual transmission it is a type of shaft having splines over its cross-section over which input pulleys are mounted, the power source for this input shaft is engine which means continuously variable transmission gets the input from the engine through input shaft.

2. Output shaft-

It is the type of shaft which is kept parallel to the input shaft in a continuously variable transmission, same as input shaft it also has splines over its cross-section and is mounted upon by output pulleys.

Output shaft is responsible to transmit final output power to the final drive of the vehicle.

4. Belt or Chain

The belt in most CVT systems is a heavy duty 'V-belt' which is V-shaped in cross section. They are made of rubber components reinforced with Kevlar and other materials to enhance durability.

In a Cvt transmission a v-shaped metallic (rubber in some case) chain or belt is used to transmit power from input pulleys to the output pulleys as this belt or chain is wrapped over both conical input and output pulleys pairs and the V-shape of this belt or chain make it possible to shift gears from high torque to the high speed.

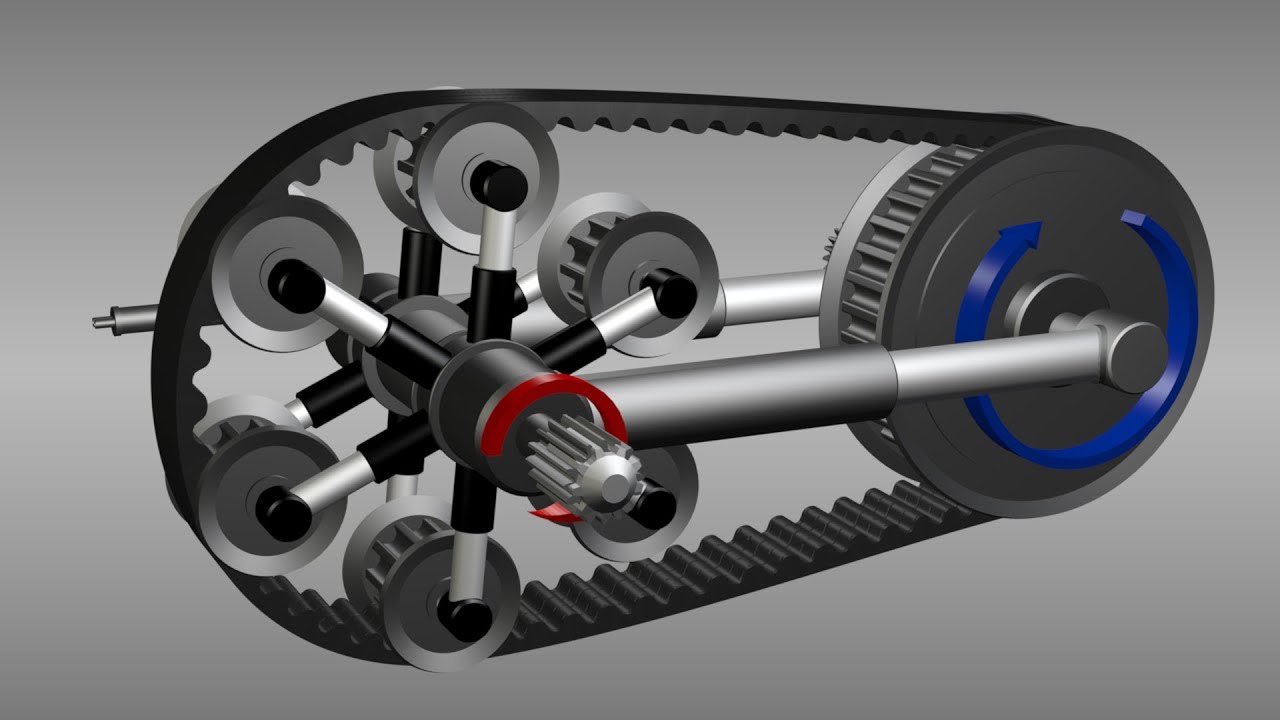

HOW CVT WORKS?

A CVT uses a pulley and belt system to change the vehicle's drive-wheel speed and torque in relation to engine speed and torque so as to provide an unlimited range of gear ratios. It is different from the automatic transmission which has a set number of gear ratios. A CVT uses components such as a high density rubber/metal belt, a driving pulley actuated by a hydraulic cylinder, a mechanical torque-sensing driving pulley, sensors and microprocessors to perform its function.

The transmission has the ability to change continuously by using an infinite number of gear ratios between maximum and minimum values. To facilitate different gear ratios, the working diameters of the two main pulleys in the transmission need to be altered. While the pulley that is connected to the engine is called the input pulley, the one that is connected to the drive wheels is called the output pulley. One side of the pulley is fixed while the other side is movable. This movement is facilitated by a hydraulic cylinder which can change the space between the two sides of the pulley. When the pulley halves come closer to each other, the belt that runs between them goes higher on the pulley, thereby increasing the diameter of the pulley.

This is how you get the unlimited gear ratios, unlike the traditional transmission, where the ratio is changed in stages by shifting gears.

TORQUE RATIOS

when a vehicle needs high torque ratios the feeding input conical pulley (sheave) over the input shaft moves away from the fixed pulley which in turn shift part of the v-belt wrapped over the input pulleys towards the lower cross-sectional part of the conical pulley.

Simultaneously when this input pulley(sheave) moves, feeding output pulley(sheave) also moves and comes closer to the fixed output pulley which in turn shift the part of v-shaped belt wrapped over the output pulleys towards the greater cross-sectional area of the output conical pulleys and desired torque ratios is attained.

SPEED RATIOS

when the vehicle needs speed ratios, the feeding conical pulley (sheave) over the input shaft moves towards the fixed pulley which in turn shifts the part of v-shaped belt wrapped over the input pulleys towards the greater cross-sectional part of the conical input pulleys.

Simultaneously with this movement of input pulley, feeding output pulley (sheave) also moves and go away from the fixed pulley which in turn moves the part of the v-shaped belt wrapped around the output pulleys towards the lower cross-sectional part of the conical output pulleys and desired speed ratio is attained.

In other words, torque ratios are achieved when the v-belt rotates at the lower cross section of the input pulleys and at the greater cross section of the output pulley.

And speed ratios are achieved when v-belt rotates at the higher cross section of the input pulley and lower cross-section of the output pulley.

TYPES OF CVT

1. Pulley Based

Compared to manual or automatic transmission systems, the design of a pulley-based CVT is simpler, with a lesser number of parts involved. The prime parts involved in such a system, are a variable diameter input pulley, an output pulley, and a V-belt that connects these two pulleys, along with several electronic devices. A change in gear ratios is achieved through the variation of distance between the pulleys and their variable diameter.

2. Toroidal CVT

This second type of design is similar in principle to a pulley-based CVT but still slightly different. The parts involved here are power rollers and discs, instead of pulleys and belts. There are two disks involved with two rollers in between. The gear ratios are changed through the use of an ingenious mechanism, which involves a peculiar arrangement of the disk and rollers. The rollers control the torque distribution and make infinitely many gear ratios possible, between the two extremes.

3. Hydrostatic CVT

These types of CVT systems use hydrostatic pumps and motors as constituent parts. The torque distribution is made possible through fluid displacement and you have a continuous range of gear ratios to choose from. Your transmission problems are substantially lowered due to the use of hydraulics and elimination of friction-prone points of contact.

Continuously Variable Transmission (cvt)

ADVANTAGES AND DISADVANTAGES

Advantages

• Better fuel consumption than a regular automatic transmission as the CVT is able to keep the car in its optimum power range regardless of speed

• There is improved acceleration due to the lower power loss experienced

• Stepless transmission

• It has the ability to allow the engine to rev almost immediately which delivers maximum torque.

• Provides a smoother ride than automatic transmission

• The hydraulic motor of the Hydrostatic CVT can be mounted directly onto the wheel hub and this allows for a more flexible suspension system and this in turn eliminates efficiency losses due to the friction from the driveshaft.

• Adapts to varying road conditions and power demands to allows for a better ride

• Better emission control and less greenhouse gas emissions because of improved control of the engine's speed range.

Disadvantages

• Driving a vehicle with a CVT is a very different experience and many drivers to not like it because you do not feel the engine accelerating; you do not feel any shifts instead you feel the engine racing as it would with a slipping clutch or a failing transmission which is just the CVT adjusting to provide optimal power.

• Higher cost

• Belt-driven CVTs (VDP system) have a limited amount of torque, however the technology is constantly being improved.

• Transmitting motion by friction causes greater wear

• Require special oil and other materials

Related posts:

Continuously Variable Transmission Definition

Continuously Variable Transmission : Components , Working , Types , Advantages and Disadvantages

What is a CVT and does it work? How CVTs (Continuously Variable Transmissions) work. An explanation of a pulley based CVT, and how this transmission does not. A continuously variable transmission (CVT) is a type of automatic car transmission system that uses a pulley and belt system to provide an unlimited range of gear ratios. In 1984, the Japanese automobile manufacturer, Subaru, introduced the electronic continuously variable transmission (ECVT) in a hatchback called Subaru Justy. A continuously variable transmission in a vehicle senses the accelerator input with engine load and get shifted to the desired speed or torque gear ratio automatically, in other words we can say that a cvt transmission is one of the simplest types of automatic transmission that provides continuous uninterrupted power within a specified range of speed and torque ratios. The CVT is the newest type of transmission. It is sometimes referred to as the shiftless transmission and is a type of automatic. What Does CVT Stand For? Autotrader explains the term CVT stands.

A CVT or Continuously Variable Transmission is an automatic, single speed, and gearless transmission that can shift through an infinite number of gear ratios.

A continuously variable transmission (CVT) is a transmission that operates on an ingenious pulley system that automatically varies the transmission ratio, allowing an infinite variability between highest and lowest gears with no discrete steps or shifts. CVTs provide more useable power, better fuel economy and a smoother driving experience than traditional transmissions that use gearboxes with fixed numbers of gear sets.

A continuously variable transmission system is a type of automatic transmission in which an arrangement of pulleys and belts made it possible for a drive to achieve n-number of continuous gear ratios within a range (depends on the design).

Read more : Why there is no clutch in gearless scooter – CVT Explained

A continuously variable transmission in a vehicle senses the accelerator input with engine load and get shifted to the desired speed or torque gear ratio automatically, in other words we can say that a cvt transmission is one of the simplest types of automatic transmission that provides continuous uninterrupted power within a specified range of speed and torque ratios.

COMPONENTS OF CVT:

1. Clutches

I. Primary clutch

The primary clutch is an advanced form of centrifugal clutch and is typically mounted to the output end of the engine crankshaft. The clutch has two sheave faces; one that is laterally fixed (stationary sheave), and one that can move in and out to engage the belt (moveable sheave). In most systems, at idle the sheave surfaces are spread at their widest spacing, the belt is riding on the post or shaft at the smallest diameter of the clutch, and the belt is not pinched by the sheave faces. This provides a 'neutral' position that allows the engine to idle without transmitting power to the wheels.

II. Secondary clutch

The secondary clutch is mounted to the input shaft of the transmission, transaxle, or the like. In modern CVT systems such as those used in recreational vehicles, the secondary clutch has two functions: as a 'slave' to the primary clutch and to provide a torque sensing element.

2. Pulleys

In Cvt pulleys play an important role as the conical shape pulleys integrated over input and output shafts are the reason for continuously variable transmission's continuous n-number of speed and gear ratios, due to the different cross section of these conical pulleys multiple torque and speed ratios are obtained.

Two pair of conical pulleys each for input and output shafts are used in a basic continuously variable transmission that are-

1. Fixed input pulley-

It is a conical pulley mounted over the input shaft (on the right-hand side), this pulley does not move (too and fro) over the shaft but rotates with the input shaft, usually fixed pulley is smaller in size.

2. Fixed output pulley

It same as fixed input pulley but unlike fixed input shaft this shaft is placed on the left-hand side over the output shaft.

3. Feeding input pulley or sheave-

It is the type of conical pulley which is mounted over the input shaft and have inner splines meshed with the shaft splines in such a fashion that it can move (too and fro) as well as rotates with the input shaft. the too and fro moment of this shaft over the input shaft make it possible to shift gear ratios.

4. Feeding output pulley or sheave

Same as moving input pulley but unlike moving input shaft, this shaft is placed on the right-hand side over the output shaft.

3. Shafts

Same as manual transmission type 2 shafts are needed by Cvt transmission to transfer power from engine to the final drive that are-

Argon and helium. 1. Input shaft-

Same as the manual transmission it is a type of shaft having splines over its cross-section over which input pulleys are mounted, the power source for this input shaft is engine which means continuously variable transmission gets the input from the engine through input shaft.

2. Output shaft-

It is the type of shaft which is kept parallel to the input shaft in a continuously variable transmission, same as input shaft it also has splines over its cross-section and is mounted upon by output pulleys.

Output shaft is responsible to transmit final output power to the final drive of the vehicle.

4. Belt or Chain

The belt in most CVT systems is a heavy duty 'V-belt' which is V-shaped in cross section. They are made of rubber components reinforced with Kevlar and other materials to enhance durability.

In a Cvt transmission a v-shaped metallic (rubber in some case) chain or belt is used to transmit power from input pulleys to the output pulleys as this belt or chain is wrapped over both conical input and output pulleys pairs and the V-shape of this belt or chain make it possible to shift gears from high torque to the high speed.

HOW CVT WORKS?

A CVT uses a pulley and belt system to change the vehicle's drive-wheel speed and torque in relation to engine speed and torque so as to provide an unlimited range of gear ratios. It is different from the automatic transmission which has a set number of gear ratios. A CVT uses components such as a high density rubber/metal belt, a driving pulley actuated by a hydraulic cylinder, a mechanical torque-sensing driving pulley, sensors and microprocessors to perform its function.

The transmission has the ability to change continuously by using an infinite number of gear ratios between maximum and minimum values. To facilitate different gear ratios, the working diameters of the two main pulleys in the transmission need to be altered. While the pulley that is connected to the engine is called the input pulley, the one that is connected to the drive wheels is called the output pulley. One side of the pulley is fixed while the other side is movable. This movement is facilitated by a hydraulic cylinder which can change the space between the two sides of the pulley. When the pulley halves come closer to each other, the belt that runs between them goes higher on the pulley, thereby increasing the diameter of the pulley.

This is how you get the unlimited gear ratios, unlike the traditional transmission, where the ratio is changed in stages by shifting gears.

TORQUE RATIOS

when a vehicle needs high torque ratios the feeding input conical pulley (sheave) over the input shaft moves away from the fixed pulley which in turn shift part of the v-belt wrapped over the input pulleys towards the lower cross-sectional part of the conical pulley.

Simultaneously when this input pulley(sheave) moves, feeding output pulley(sheave) also moves and comes closer to the fixed output pulley which in turn shift the part of v-shaped belt wrapped over the output pulleys towards the greater cross-sectional area of the output conical pulleys and desired torque ratios is attained.

SPEED RATIOS

when the vehicle needs speed ratios, the feeding conical pulley (sheave) over the input shaft moves towards the fixed pulley which in turn shifts the part of v-shaped belt wrapped over the input pulleys towards the greater cross-sectional part of the conical input pulleys.

Simultaneously with this movement of input pulley, feeding output pulley (sheave) also moves and go away from the fixed pulley which in turn moves the part of the v-shaped belt wrapped around the output pulleys towards the lower cross-sectional part of the conical output pulleys and desired speed ratio is attained.

In other words, torque ratios are achieved when the v-belt rotates at the lower cross section of the input pulleys and at the greater cross section of the output pulley.

And speed ratios are achieved when v-belt rotates at the higher cross section of the input pulley and lower cross-section of the output pulley.

TYPES OF CVT

1. Pulley Based

Compared to manual or automatic transmission systems, the design of a pulley-based CVT is simpler, with a lesser number of parts involved. The prime parts involved in such a system, are a variable diameter input pulley, an output pulley, and a V-belt that connects these two pulleys, along with several electronic devices. A change in gear ratios is achieved through the variation of distance between the pulleys and their variable diameter.

2. Toroidal CVT

This second type of design is similar in principle to a pulley-based CVT but still slightly different. The parts involved here are power rollers and discs, instead of pulleys and belts. There are two disks involved with two rollers in between. The gear ratios are changed through the use of an ingenious mechanism, which involves a peculiar arrangement of the disk and rollers. The rollers control the torque distribution and make infinitely many gear ratios possible, between the two extremes.

3. Hydrostatic CVT

These types of CVT systems use hydrostatic pumps and motors as constituent parts. The torque distribution is made possible through fluid displacement and you have a continuous range of gear ratios to choose from. Your transmission problems are substantially lowered due to the use of hydraulics and elimination of friction-prone points of contact.

Continuously Variable Transmission (cvt)

ADVANTAGES AND DISADVANTAGES

Advantages

• Better fuel consumption than a regular automatic transmission as the CVT is able to keep the car in its optimum power range regardless of speed

• There is improved acceleration due to the lower power loss experienced

• Stepless transmission

• It has the ability to allow the engine to rev almost immediately which delivers maximum torque.

• Provides a smoother ride than automatic transmission

• The hydraulic motor of the Hydrostatic CVT can be mounted directly onto the wheel hub and this allows for a more flexible suspension system and this in turn eliminates efficiency losses due to the friction from the driveshaft.

• Adapts to varying road conditions and power demands to allows for a better ride

• Better emission control and less greenhouse gas emissions because of improved control of the engine's speed range.

Disadvantages

• Driving a vehicle with a CVT is a very different experience and many drivers to not like it because you do not feel the engine accelerating; you do not feel any shifts instead you feel the engine racing as it would with a slipping clutch or a failing transmission which is just the CVT adjusting to provide optimal power.

• Higher cost

• Belt-driven CVTs (VDP system) have a limited amount of torque, however the technology is constantly being improved.

• Transmitting motion by friction causes greater wear

• Require special oil and other materials

Related posts:

Continuously Variable Transmission Definition

Subaru Continuously Variable Transmission

Valvoline's CVT fluid is designed for today's technologically advanced variable transmissions. It is formulated with full-synthetic, premium base oils, long-life friction modifiers, unique anti-wear additives and shear stable viscosity modifiers that help prevent oil film breakdown. Recommended for use in the following CVT applications: Audi and VW (TL 52180; G 052 180), Ford (CVT30/Mercon C), Subaru (Lineartronic CVTF), Honda (HMMF), Nissan (NS-2), Mitsubishi (CVTF-J1/SP-III), BMW Mini Cooper (EZL 799), Hyundai and Kia (SP-CVT 1), Suzuki (TC/NS-2/CVT Green1), Dodge, Jeep (NS-2/CVTF+4), GM Saturn (DEX-CVT), Ford (CVT23), Mercedes Benz (236.20).

PI SHEET|SDS

- OR -